Thermal paper definition and application

December 06, 2024

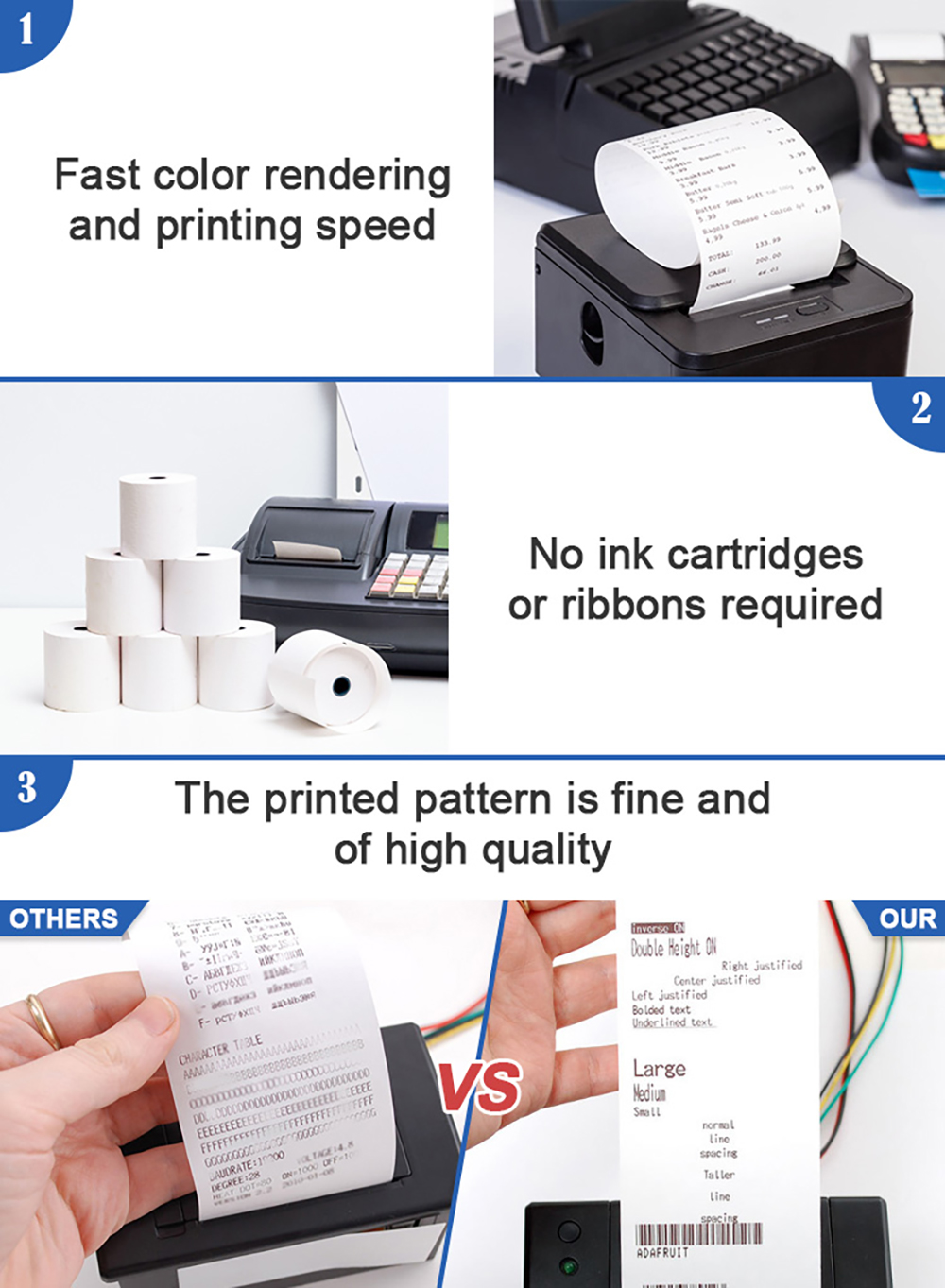

Thermal printers can only use special thermal paper. Thermal paper is coated with a layer that changes color when exposed to heat. It is similar to photographic film, but this layer is discolored when exposed to heat. With this characteristic of the heat-sensitive coating, thermal printing technology has emerged.

Thermal paper is a special coated paper that looks similar to plain white paper. The surface of thermal paper is smooth, which is made of ordinary paper as paper base, coated with a layer of heat-sensitive coloring layer, and coated on the surface of ordinary paper. The chromophoric layer is made of adhesive, developer, and colorless dye (or The composition is called leuco dye, which is not separated by microcapsules and the chemical reaction is in a "latent" state. When the thermal paper encounters a heat-generating print head, the color-developing agent at the print head and the leuco dye undergo a chemical reaction and change color to form a graphic.

When thermal paper is placed above 70°C, the heat-sensitive coating begins to change color. The reason for its discoloration also depends on its composition. The heat sensitive components in the thermal paper coating are mainly two kinds: one is a leuco dye or a leuco dye; the other is a color developer. This kind of thermal paper is also called a two-component chemical type thermal recording paper.

Thermal paper has developed rapidly with the popularity of fax machines throughout the world. However, due to the development of electronic communications, thermal paper has not only spread to personal homes in the form of fax paper, but has also appeared in commercial, supermarkets, banks, etc. Hospitals, airports and other fields. Its use has become increasingly widespread, the variety is increasing, and the appropriate range is becoming wider and wider. At present, the main areas of application are as follows.

(1) Thermal paper for fax machines is mainly used for various models of thermal paper fax machines. There are commercial businesses, family businesses, etc. At present, thermal paper machines for such applications account for about half of the total output, and are the main direction of thermal paper since the late 1980s. Its quality goal is to pursue the high speed of fax recording, the high density of lines (blackness) and the preservation after recording. If we look at the recording speed, we have evolved from the G2 model to the G3 model and even to the G4 model, which can achieve high-speed faxing of about 15 seconds per sheet of A4 size paper.

(2) Thermal paper for printing and terminal recording To meet the needs of various new terminal recording devices, various types of products have been developed, which can be widely used for printing records in word processors, medical inspections, and industrial inspections. Printed with production (abbreviated as CAD/CMA), counters, cash automatic payment machines (ATM/CD), and portable terminal printers, receipt records of highways, taxis, etc.

(3) Labels and Bills Thermal Paper Thermal Paper In recent years, new products have been introduced to the label industry, and the development speed has been improved. It is a combination of thermal paper and self-adhesive labels. The back of thermonuclear paper is coated with adhesive and compounded on release paper for labels to be printed.