Principle of thermal sensitivity

The core of thermal paper is its thermal coating. It is mainly composed of colorless dyes, color developing agents and sensitizing agents. When stimulated by the appropriate heat energy, the colorless dye and the color developer undergo a chemical reaction, resulting in a color change to achieve the printing of information. This thermal reaction is the key to the ability of thermal paper to record text, images and other information.

Printing application

Express industry: It is widely used in express side single printing. It can quickly and efficiently print out all kinds of information required for express packages, such as recipient name, address, contact information, tracking number, etc. Its printing speed is fast and no consumables such as ink cartridges or ribbons are required, making it ideal for the high-traffic printing needs of the express delivery industry.

Cashier receipt: Printed paper used as a cashier receipt in the retail industry. Can clearly print out commodity information, prices, trading hours and other content. Its high definition and fast printing features make the checkout process faster and more accurate.

Label printing: Used to make a variety of labels, such as commodity price labels, inventory labels, etc. Thermal label paper can easily print the required text and bar code information, and you can select different sizes and characteristics of thermal label paper according to different application scenarios.

Performance characteristics

High definition: The ability to print clear, sharp text and images. The printing resolution can reach a high level to ensure the readability of the printed information. For example, when printing bar codes and QR codes, it is possible to guarantee that the scanning device can accurately read the information.

High speed: The printing speed of thermal printing technology has great advantages over traditional printing methods. In high-speed printing mode, several inches of content can be printed per second, which is very important for occasions where a large number of prints are required.

Durability: It has certain anti-wear and anti-scratch ability. Under normal use, the information printed on it can be maintained for a period of time without fading or blurring. At the same time, it also has a certain tolerance to environmental factors such as humidity and temperature, but extreme environments may affect its performance.

Quality factor

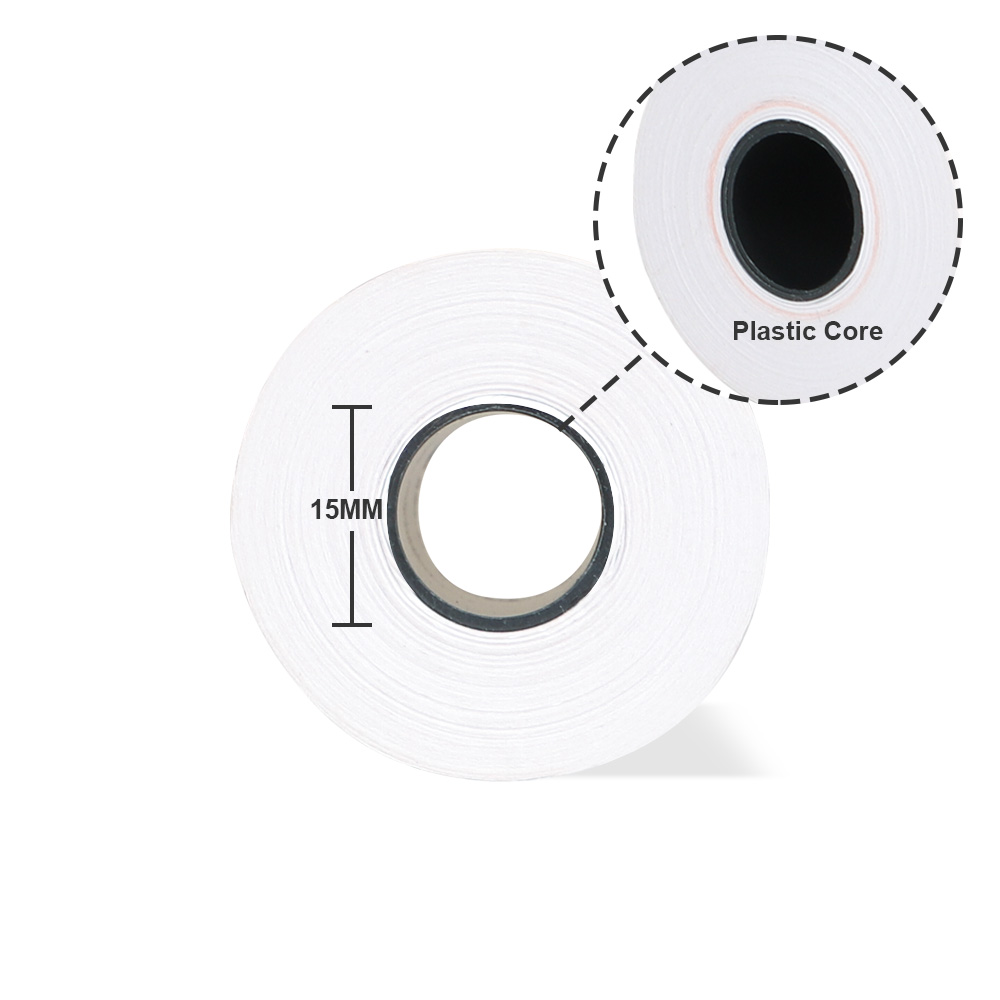

Paper quality: including the thickness, strength and smoothness of the paper. Thicker paper can withstand a certain physical pressure, suitable for long-term storage or may be subjected to friction occasions; The smooth surface of the paper is conducive to the smooth movement of the print head and improve the print quality.

Thermal coating quality: The uniformity and stability of thermal coating directly affect the printing effect and storage time. High quality thermal coatings guarantee the clarity and durability of printed information.

Preservation condition

Thermal paper should be stored in a cool, dry environment. Avoid direct sunlight and high temperature and humidity, as these factors may cause the heat-sensitive coating to react prematurely, causing problems such as discoloration, blurring, or loss of information on the paper. At the same time, it is also necessary to avoid contact with chemical substances to prevent damage to the heat-sensitive coating.

Environmental protection property

Some thermal papers pay attention to environmental protection in the production process, using recyclable materials or coating materials that meet environmental standards. In the post-use treatment, due to its relatively simple composition structure, it is also relatively easy to recycle, in line with the requirements of modern society for environmentally friendly packaging materials.